The Essential Role of Crankshafts in Diesel Engines

The crankshaft is a crucial component in the internal combustion engine, particularly in diesel engines. This piece of machinery plays a vital role in converting the linear motion of the pistons into the rotational motion required to power the vehicle. Understanding the mechanics, components, and maintenance aspects of crankshafts can help both consumers and mechanics appreciate their significance in the operation of diesel engines.

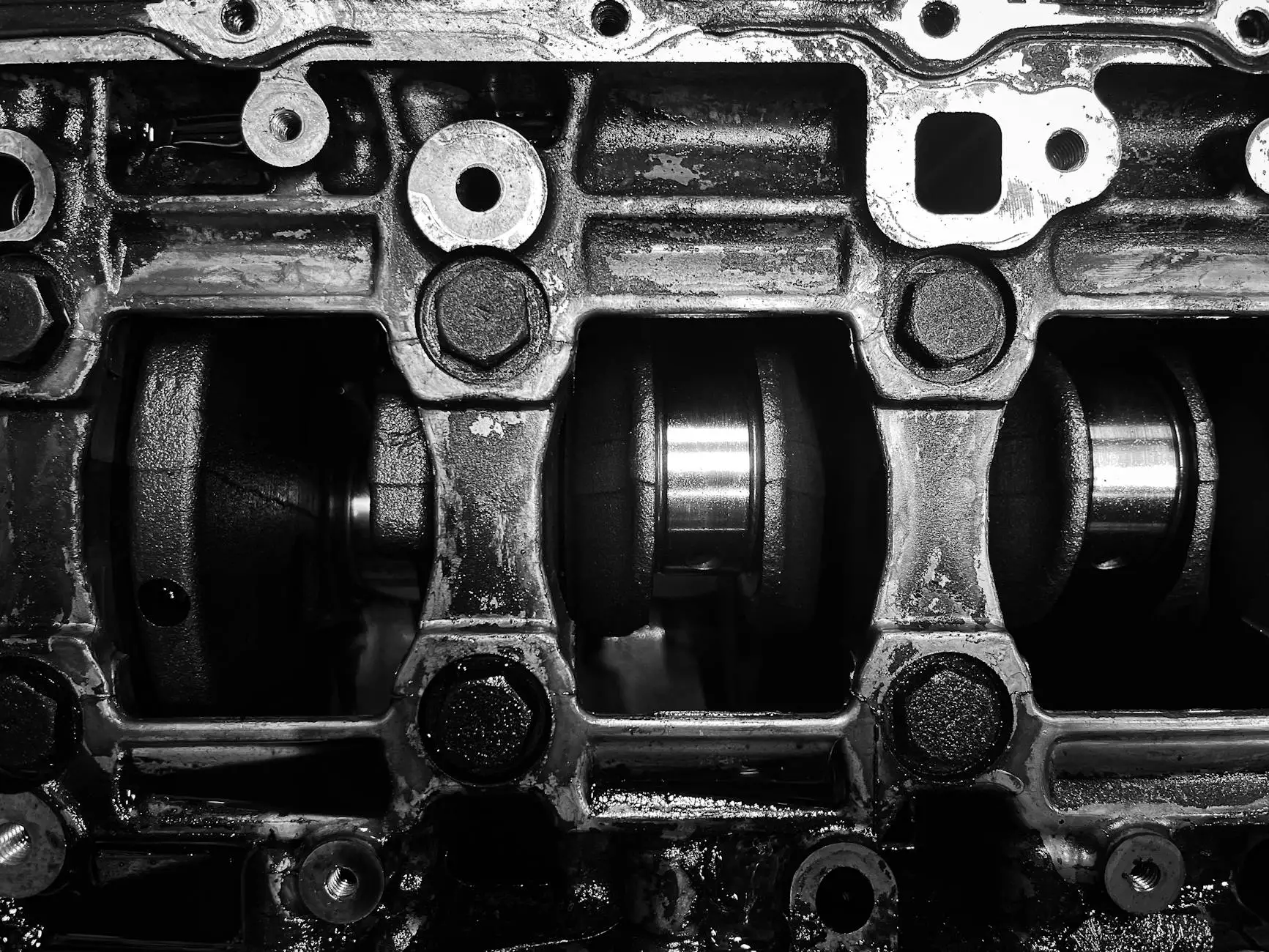

What is a Crankshaft?

A crankshaft is a long rod made of steel or iron, meticulously designed to withstand the immense forces generated during engine operation. Its primary function is to convert energy generated from fuel combustion into a usable mechanical form. In simple terms, the crankshaft translates the up-and-down motion of the pistons into a circular motion that ultimately keeps the vehicle moving.

Components of a Crankshaft

Understanding the intricate design of a crankshaft involves recognizing its numerous components, which include:

- Crankpins: These are the offset sections where connecting rods attach the pistons to the crankshaft.

- Main journals: These cylindrical sections are positioned at regular intervals along the length of the crankshaft and allow it to rotate freely within the engine block.

- Counterweights: These additional weights help balance the mass of the crankshaft, reducing vibration and ensuring smooth operation.

- Webs: The sections connecting the crankpins to the main journals, essential for structural integrity.

How Crankshafts Function in Diesel Engines

In diesel engines, the fuel combustion occurs at a higher compression rate compared to gasoline engines. This aspect puts additional stress on the crankshaft. The functioning mechanism is outlined in several steps:

- The combustion process pushes the piston down, leading to a linear movement.

- This movement rotates the crankpin, which is attached to the crankshaft, converting linear motion into rotational motion.

- The rotational motion is then transferred to the flywheel and subsequently to the drivetrain, propelling the vehicle forward.

Importance of Quality Crankshafts

High-quality crankshafts are essential for the overall performance and longevity of a diesel engine. Investing in quality parts ensures:

- Durability: Quality materials withstand the stress and heat generated during operation.

- Performance: A well-manufactured crankshaft minimizes friction and optimizes fuel efficiency.

- Reliability: Reduces the risk of engine failure and associated repair costs.

Choosing the Right Crankshaft for Your Diesel Engine

Selecting the right crankshaft can make a significant difference in the performance of your diesel engine. Below are essential factors to consider when making a purchase:

Material Quality

Crankshafts are typically forged from steel or iron. Ensure that the materials used are of high grade, with minimal impurities to enhance durability.

Compatibility

It’s vital to ensure that the crankshaft is compatible with the specific diesel engine model. Mismatched parts can lead to insufficient performance or severe engine damage.

Manufacturing Standards

Check for manufacturing standards and certifications that indicate quality control during production. ISO-certified manufacturers typically ensure a higher quality of products.

Brand Reputation

Consider purchasing from reputable brands that are known for producing quality diesel engine parts. Customer reviews and industry recommendations can be excellent indicators of reliability.

Common Issues with Crankshafts

Despite their robust design, crankshafts can encounter several issues over time. Being aware of common problems can help you to address them promptly:

- Crankshaft Bending: This can occur due to excessive force or sudden stops, affecting engine performance.

- Wear and Tear: Regular usage can lead to wear on bearings which can result in noise and vibration.

- Crankshaft Damage: Sudden engine failure or overheating can cause cracks or breaks in the crankshaft.

Maintenance Tips for Crankshafts

Regular maintenance of your crankshaft can prolong its life and improve engine performance. Here are some tips:

- Regular Oil Changes: Engine oil lubricates the crankshaft and its bearings. Old or contaminated oil can cause increased friction, leading to wear.

- Monitor Engine Temperature: Overheating can lead to severe damage. Keep an eye on your engine's temperature gauge.

- Inspection for Vibrations or Noises: Unusual sounds or vibrations can indicate crankshaft issues. Address these promptly to avoid further damage.

Where to Find Quality Crankshafts

For those looking to purchase a new crankshaft, client-diesel.com offers a variety of high-quality diesel engine parts, including crankshafts. Their commitment to quality ensures that you receive parts that meet or exceed industry standards.

Why Choose Client Diesel?

- Wide Range of Products: They offer a comprehensive selection of diesel engine parts including spare parts for various models.

- Expert Support: Their knowledgeable staff can assist you in finding the perfect crankshaft tailored to your engine's needs.

- Competitive Pricing: Quality doesn't have to break the bank. Client Diesel offers quality parts at reasonable prices.

Conclusion

Understanding the role of the crankshaft in a diesel engine is critical for anyone involved with automotive mechanics or maintenance. Investing in quality crankshafts from a reputable supplier like client-diesel.com not only enhances engine performance but also contributes to vehicle longevity. Regular maintenance and being aware of potential issues can make all the difference in ensuring a smooth and efficient operation of your diesel engine.

For further details about crankshafts and other diesel engine parts, visit client-diesel.com. Your engine's health depends on the quality of its components!

https://client-diesel.com/en/products/crankshaft